What is energy density and how does it impact drone performance?

Why pouch cells provide better performance than their cylindrical counterparts

In drone battery manufacturing, energy density describes how much energy a battery can store relative to its size or weight. Beyond safety, temperature rise and cycle life, it’s one of the most important metrics in designing high-performance batteries for unmanned aircraft systems (UAS), however it’s not the only one to consider when buying your next battery. Energy density is certainly a common buzzword in the industry and many companies promote high figures but fail to acknowledge the drawbacks to their designs. The reality is that battery safety should always be the highest priority and misleading specifications is contradictory to that goal. So, with this in mind, read on to learn more about what energy density actually means, how to maximize it, and why it’s not the only consideration you need to consider when buying your next battery.

Optimizing a battery pack’s energy density is not a straightforward outcome. There are always tradeoffs. Typically, as energy density increases, the discharge rate, temperature rise, and cycle life is reduced. Likewise, achieving a higher discharge rate comes at the cost of lower energy density. Determining what your mission objectives are, and the power requirements of your platform, are essential to picking the proper battery. Badland Batteries’ engineers have made that easier for you by formulating a unique method of combining cathode, anode, and electrolyte materials into pouch cells that deliver the best combination of high energy density and high discharge rates.

One reason Badland Batteries accomplishes this is by using pouch cells, which reduces the amount of inactive material and allows for a more compact design with good packing density due to their rectangular shape. They are manufactured in smaller batches with a flexible stacking process, which allows the newest technologies to be incorporated as well as chemistry tuning for different energy density, discharge rates, and scalability to different sizes and shapes.

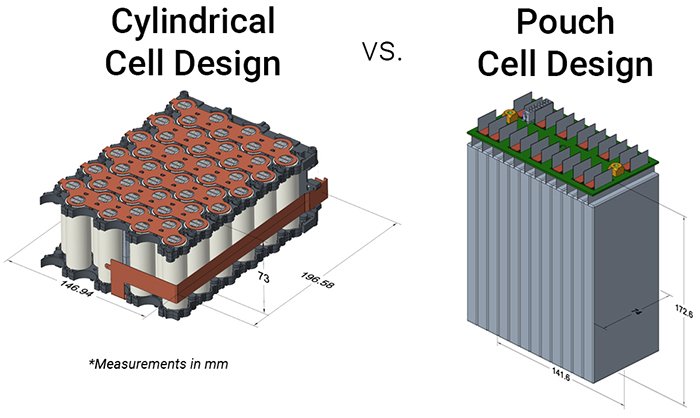

Cylindrical cells are mass produced, cost effective, and readily available from multiple sources. However, they have significant drawbacks for UAS battery designs. They are typically heavier and have air gaps due to their shape, which creates a larger overall footprint. Because pouch cells are stacked, there is a larger electrode surface area and better availability to optimize layering for specific missions such as higher power or higher energy. Cylindrical cells often can not support high discharge current applications in small form factors whereas pouch cells can deliver the power needed in a compact size.

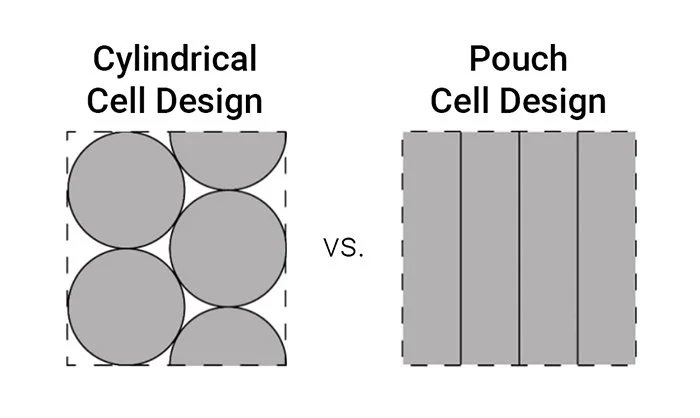

When cylindrical cells are combined into packs and modules, the circular cross-section does not allow for full utilization of the available space, which results in lower packaging density. In contrast, the electrode and separator layers of a pouch cell are stacked rather than rolled. This structure allows for significantly higher packaging density. Calculating the energy density between the above simplified cell designs assuming the same overall battery volume is determined by:

Cylindrical cell design: Area = 4 * π * r^2

Pouch cell design: Area = 4 * r * (2r + √ ((2r)^2 - r^2)) = 4*(2+1.73) * r^2

In this example, the cylindrical cell design allows for only 84.2% of the energy density compared to the pouch cell volume equivalent.

In summary, pouch cells deliver superior energy density compared to cylindrical cells due to their lightweight, flexible packaging that minimizes inactive materials and maximizes active, energy-storing components. Their flat form factor enables tighter stacking and more efficient use of available volume, eliminating the wasted space common with cylindrical cell packs. Pouch designs also support larger, more uniformly loaded electrodes, reducing internal resistance and improving thermal behavior — both of which allow for increased electrode thickness and overall capacity. Together, these advantages make pouch cells the most effective format for achieving high energy density in UAS platforms.

Questions? Reach out today to talk with one of our battery experts!